Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill).

Impact Crusher - an overview | ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to fully utilize the high-speed impact energy of entire rotor.

Impact Crusher VS Jaw Crusher:What Are the Differences?

Disadvantages of impact crusher: The blow bar and impact plate are easy to wear and need to be replaced frequently. 4. Crushers Application. 1) Jaw crusher is widely used in many fields such as mining, smelting, building, highway, railway, waterpower and stone industry, crushing various materials with compressive strength not exceeding 320 MPa.

Impact Crushers | Crush Rock, Minerals & More | Williams ...

Using an advanced impact method, impact crushers are the efficient and cost-effective solution for industrial size reduction projects. Impact Crushers have a wide range of industrial applications from crushing rock to de-lumping sand and whole lot more. Browse Williams Crusher’s line of impact crushing machines.

applications of impact rock crusher in india

Features and Applications of Impact Rock Crusher-1wg1. 2014-6-11 · When it comes to the applications, the impact rock crusher, jaw crusher, cone crusher, rock crusher, they are used for crushing various rocks, constructing railway, expressway roadbed and dam area of power station, producing artificial materials for the building /pics/

liming NP series impact crushers Wear parts application ...

NP Impact crusher contains mainly three different groups of wear parts: Blow bars, Breaker plate liners and Side wear plates. Feed liners and Discharge lip for conveyor in Mobile applications can be considered as a wear parts. The blow bar is the component of an impact crusher most strongly subjected to mechani-cal stress.

Crushing technology

Depending on hardness, crushability and abrasiveness, wear costs – related solely to the jaw crusher – are significantly lower than with impact and cone crushers. Cone crushers Cone crushers are the choice for use in medium-hard to hard and abrasive natural stone as well as for raw material preparation in mining applications.

Impact crusher has a wide application range - GOLD NUGGET ...

During the actual usage of impact crusher in road construction, the impact crusher is used in the second process. This crusher has many crushing chambers, and the materials go through coarse crushing and fine crushing until their granularity meets the customers requirement. Its working principle ...

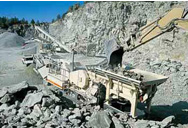

Mobile crushers and screens - liming Mining and Rock ...

The Prisec™ impactor revolutionizes performance and versatility in mobile impact crushing. Available in open or closed circuit, the QI Mobile impact crusher series offers unparalleled levels of control, flexibility and productivity in recycling and quarrying applications. liming offer a range of single, double, and triple deck screening ...

VSI Vertical Shaft Impact Crusher

Usage and Application VSI impact crusher is a classic type of fine crushing equipment, which fully embodies advanced fine crushing technology. It is mainly used for the production of high-quality sand and stone aggregate for the construction of highways, high-speed railways, hydropower projects, airports and other construction projects.

Impact crushers - high-quality impactors - liming

Impact crushers are utilized in aggregates production, mining operations, as well as in recycling applications. Depending on the type of an impact crusher, they are known for either high reduction ratios or capabilities to produce precisely shaped, cubical end products.

Impact crusher,Impact crusher for sale, PF impact crusher ...

Application: Impact crusher is widely used for crushing stone in mining, highway, railway, construction, etc. It is an irreplaceable crushing equipment for high-grade sand and gravel. Working principle: Impact crusher is a kind of stone crusher using impact energy. After turn on,the motor drives the rotor rotate at a high speed .When the ...

liming NP15 impact crusher animation - YouTube

Jan 31, 2014 · limings new liming NP13 and NP15 impact crushers provide significant improvements for your productivity, safety and uptime. ... Especially for secondary and tertiary applications, the optimized ...