Most Profitable India Cement Maker Reopens But Sees Demand ...

May 04, 2020 · Star Cement Ltd., the most profitable maker of the construction material in India, stone demand fall 80% after authorities partially lifted the world’s biggest lockdown.

crushing and grinding of raw material in a cement industry

How we make Cement - Sharrcem. The raw materials for cement production are mined by the use of explosives (drilling As the mill rotates, the grinding media crush the raw materials into powder. Raw Material Preparation - Cement Plants and Kilns in Britain and . Preparation of cement raw materials.

Raw Materials Used in Cement Industry CMA India

The second largest cement industry in the world, the Indian Cement industry stands at 545 MTPA of installed capacity as of 2019. Limestone comprises 95% of core raw material for cement production. No wonder then that the cement sector governs demand, supply and pricing of limestone (as well as coal) to some extent.

Cement Raw Materials used in Manufacturing of Cement

Raw materials used for manufacturing of Portland cement are found naturally in the earth’s crust. It is made primarily from calcareous and argillaceous materials and gypsum. Calcareous materials contain limestone or chalk while argillaceous materials comprise an oxide of silica-alumina and iron. Both are found as clay or shale.

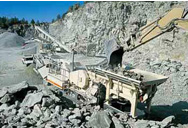

Cement raw materials crushing plant

Cement GrafGalenStrae 17 Industry Phone 49. Crushing The raw material is crushed to the size of coarse gravel 2 Interim storage blending The raw material is stockpiled or homogenized in blending beds rent cement types in a given plant the plexity of cement grinding systems is growing constantly and the plant design require

Unshaped products - Castables & High Alumina Cement

Products are also designed using best possible raw materials available across the Globe. Manufacturing of Unshaped and/or Monolithic Refractories is the key strength of the organization. These classes of material include Castables (Conventional, Low Cement, Ultra Low cement and No Cement); Mortars; Gunning Mass; Ramming Mass; Plastics;

Cement industry worried as raw material evaporating fast ...

Royalty on different raw materials has also been increased. According to Mahmood, the government has pushed up the royalty on limestone to Rs60 from Rs5 per ton. The Khairpur plant alone consumes ...

RAW MATERIALS FOR CEMENT: Middle Eastern suppliers eye ...

Published by: The Daily Star, December 17, 2019 Middle East-based cement raw materials exporters are keen to expand their sales in Bangladesh as the country is increasingly scaling up its manufacturing capacity to produce the key construction material to feed the growing economy. Cement manufacturers imported raw materials such as clinker, fly ash, iron slag, […]

Case Study Manual on Alternative Fuels & Raw Materials ...

Case Study Manual on Alternative Fuels & Raw Materials Utilization in Indian Cement Industry 1.0 EXECUTIVE SUMMARY India is the 2nd largest producer of cement in the world with total installed capacity of about 260 Million MTPA as on March 2010. Cement industry in India is a fast growing sector and is expected to

Raw materials - Cement

The most common raw rock types used in cement production are: Limestone (supplies the bulk of the lime) Clay, marl or shale (supplies the bulk of the silica, alumina and ferric oxide) Other supplementary materials such as sand, fly ash/pulverised fuel ash (PFA), or ironstone …

crushing and grinding of raw material of cement

crushing the raw materials of cement. Crushing And Grinding Of Raw Material In A Cement The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the cement building material Britannica The cement-making process, from crushing and grinding of raw materials, through roasting of the ,..

Raw Materials Required For Cement Grinding Units

Raw Materials Required For Cement Grinding Units ... mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel, concrete, etc. ... Double roller crusher used for activated charcoal crushing india. stone ...

Crusher Grinder Of Raw Materials For Cement

Crushing Of Raw Material For Cement process crusher. Crushing of raw materials for cement - Crusher Unit cement production line cement making plant is used in cement raw material crushing plant lilimingne crushing lilimingne.

DRAFT of Embodied Energy and Global Materials

The raw materials are extracted, homogenized, kilned and ground. The result is ground clinker, a necessary ingredient in all types of cement. The percentage of input raw materials for the production of ordinary Portland cement is cement clinker (95%), gypsum (5%) and a small amount of ethylene glycol (0.006%).

Raw Mill,Raw Mill In Cement Plant

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Raw mill is mainly used in grinding raw materials and end products in cement plant.

11.6 Portland Cement Manufacturing - US EPA

Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites.

china vrm cement raw material india

Raw Mill Grinding Process India; Raw Mill In Cement Plant,Cement Making Plant. Its a key equipment for grinding materials, widely used in powder-making production line such as cement, silicate sand, new-type building material, ore dressing of ferrous metal and non-ferrous metal, etc.

Indian cement prices may increase this week

Before the increase, the price of a 50kg cement bag rests between INR300-80 depending on the grade. Some producers are reporting that, following the permission to start-up operations again, it will take time to scale up production because of the lack of the required workforce, raw materials and transportation, amongst other reasons.