Ball Mill Grinding Theory - Crushing …

Table of ContentsOpen Circuit GrindingClosed Circuit GrindingSingle Stage GrindingTwo Stage GrindingFirst Stage of Ball MillingSecond Stage of Ball MillingLarge VS Small Grinding BallsRelation between Speed of Mill & Size of Balls in MillDeductions from Operating TestsDesign & Regulation of a Fine Crushing PlantMechanics inside a Ball MillAction of Charge at Slow SpeedMotion of Charge at ...

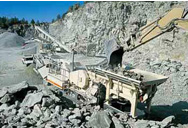

ball mill grinding machine syria - cruisertrailers.co.za

Ball Mill For Grinding Lime Mortar, Ball Mill,mill grinder,ball mill ... Ball Mill is a type of grinder used to grind materials into extremely fine ... A revolution counter for recording the revolutions of the mill is fixed on the machine.

ball mill grinding machine syria - …

Mill , Grinding Ball Mill Suppliers In Uae , ball mill grinding machine syria , second hand… Get Price SKF helps manufacturer extend service life for vertical roller mills

Ball Mill Design/Power Calculation

These are a good back-to-basics exercises for those wanting to understand what is behind or inside the machines. Ball Mill Grinding Capacity Calculator Ball Mill Motor/Power Sizing Calculation Ball Mill Design/Sizing Calculator The power required to grind a material from a given feed size to a given product size can be estimated by using the ...

Grinding technology and mill operations | FLSmidth

Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and stone coke, and finish cement grinding. Improving the competences of the team plays a key role in the optimal utilisation of the grinding installation in your cement plant.

Ball mill, Grinding machine, Wet ball mill, Dry ball …

22.05.2014 · Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

Grinding Machine - Ball Mill Manufacturer

Grinding machines are intended to break a solid material into smaller pieces. Grinding happens when solid material is exposed to mechanical forces that smash the structure by overcoming the interior bonding forces of the material.

Ball Mill Grinding - William Boulton

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world. Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materials.

Ball mill - Wikipedia

The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be carried out either wet or dry but the former is performed at low speed. Blending of explosives is an example of an application for stone balls.

Aavishkar Machinery Pvt Ltd- Ball Mill …

Aavishkar Machinery is well recognized company engaged in development of turnkey projects and manufacturing finest quality equipments. We are considered as major manufacturer and supplier of ball mill and various kinds of machineries like Continuous Ball Mill, Batch Type Ball Mill.Typical machineries and equipments are fabricated with precise techniques following strictly international conditions.

rotary grinding machine Syria - pulizieservice.it

ball mill machine syria - dahabvakantiehuisje.nl Deze pagina vertalen. ball mill grinding machine syria skyengineering. ball mill grinding machine syria As a leading global manufacturer of crushing, grinding and mining equipments, we ...

ball mill working principle - YouTube

08.05.2015 · Great Wall ball grinding mill process ball grinding mill working principle 3D our website:www.greatwallcorporation.com/, www.great-wall.co our email:sales@gw...

Continuous Ball Mill, Manufacturer, India

It is a kind of grinder, used to ground different types of materials like chemicals, ceramic material, paint or etc. For pottery, coal and feldspar are ground in continuous ball mill.It is also used for the fertilizer, ferro alloys, cement, pencil, marble, minerals, coal, glass ceramics and silicates.

The operating principle of the ball mill - Primo Pizza

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed ...

ball mill grinding machine syria - Jean Monnet …

Supply professional ball mill equipments including ball mill, grinding mill, wet ball mill, dry ball mill, ball milling, ... GM Series Grinding Ball Mill Machine. GM Series Grinding Ball Mill Machine.

Laboratory Grinding by Rod Mill - YouTube

19.03.2018 · Solo Survival: How to Survive Alone in the Wilderness for 1 week --Eastern Woodlands - Duration: 34:07. Tom McElroy-Wild Survival Recommended for you

Energy Saving Ball mill,Ball grinder,Ball grinding …

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different specifications.Steel balls are taken to a certain height by centrifugal force from ...

Ball Mill Critical Speed & Working Principle - …

19.06.2015 · Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM speed going from sub-critical to super-critical helps understand the Ball Mill Working ...

3D Animation Demo & working site of Ball Mill - …

12.11.2014 · Offical website:【http://www.bailingmachinery.com/】 Alibaba website:【http://zzbailing.en.alibaba.com/】 Product webpage:【http://www.bailingmachinery.com/produ ...

Grinding Mill Design & Ball Mill Manufacturer

All Grinding Mill & Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.