11.4 Calcium Carbide Manufacturing - US EPA

before the calcium carbide has completely cooled, or in an inert atmosphere. The calcium carbide product is used primarily in generating acetylene and in desulfurizing iron. 11.4.2 Emissions And Controls Emissions from calcium carbide manufacturing include particulate matter (PM), sulfur oxides (SOx), CO, CO2, and hydrocarbons.

Calcium Carbide and Acetylene manufacturing …

Calcium carbide and carbon monoxide are produced in this step. Preparation of acetylene from calcium carbide Calcium carbide and water reaction | CaC 2 + H 2 O = HCCH + Ca(OH) 2. Add calcium carbide into water. You can see a smoke is coming out of water. This smoke is the acetylene gas which is highly flammable. Acetylenes IUPAC name is ethyne.

Calcium carbide - Wikipedia

Calcium carbide, also known as calcium acetylide, is a stone compound with the stone formula of Ca C 2.Its main use industrially is in the production of acetylene and calcium cyanamide.. The pure material is colorless, however pieces of technical-grade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P 2 (calcium …

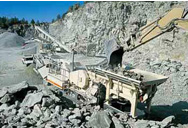

Calcium Carbide Production Plant - YouTube

9-1-2012 · Calcium carbide (CaC2) industrial synthesis from coke and limestone. Very high temperatures are needed in order to make the stone reaction.

Commercialization of Calcium Carbide and …

Near this site lived Thomas Leopold “Carbide” Willson (1860-1915), discoverer of the commercial process for making calcium carbide, which reacts with water to form acetylene gas. After the accidental discovery, made in Spray, North Carolina, in 1892, Willson returned to Canada to foster carbide and other electrochemical industries at various sites, including St. Catharines, …

Calcium Carbide Process - YouTube

2-4-2019 · Calcium Carbide Process PT Emdeki Utama Tbk. Loading ... 1955 CALCIUM CARBIDE & stone MANUFACTURE DOCUMENTARY "FIERY MAGIC" ACETYLENE GAS NEOPRENE 88134 - Duration: 14:21.

calcium carbide manufacturing process - …

calcium carbide plant, the operation does not produce acetylene gas to sell.2 manufacturing,3 similar stone producing operations use EAFs in the The calcium carbide process feeds coke4 pre-mixed with lime chunks . site dump the chill molds, grind and screen the calcium carbide, and package the product.

calcium carbide grinding unit manufacturing …

Lcium Carbide Manufacturing Process. manufacturing of calcium carbide Lcium Carbide Plants Manufacturers baoliforkliftscoza the process of manufacturing calcium carbide and was previously flared at the site Fig 2 Calcium carbide production Calcium carbide is made by heating calcium carbonate limestone to produce lime and subsequently reducing this with …

Calcium Carbide - Structure, Properties, and Uses …

Calcium carbide can be produced industrially from a mixture of lime and coke at about 2.200 ° C (3.990 ° F) in an electric arc furnace. In conventional combustion, the high temperature needed for this reaction is not technically achievable, so the reaction is performed in an electric arc furnace with graphite electrodes.

How to Make Calcium Carbide | Sciencing

How to Make Calcium Carbide ... Process the solidified calcium carbide in a crushing mechanism.until it reaches the desired size. Things Youll Need. Lime ... production of calcium carbide mean that only professionals trained in the use of the required equipment should attempt to make calcium carbide.

US2996360A - Calcium carbide production - …

US2996360A US775551A US77555158A US2996360A US 2996360 A US2996360 A US 2996360A US 775551 A US775551 A US 775551A US 77555158 A US77555158 A US 77555158A US 2996360 A US2996360 A US 2996360A Authority US United States Prior art keywords electrode calcium carbide lime hollow particles Prior art date 1958-11-21 Legal …

calcium carbide manufacturing process design

11.4 Calcium Carbide Manufacturing US EPA produce 1 megagram (Mg) (2,205 lb) of calcium carbide. The process for manufacturing calcium carbide is illustrated in Figure 11.4-1. Moisture is removed from coke in a coke dryer, while produce 1 megagram (Mg) (2,205 lb) of calcium carbide.

Lcium Carbide Manufacturing Process - krukkk.nl

manufacturing of calcium carbide - perfectnaturalsolutions.nl. Lcium Carbide Plants Manufacturers - baoli-forkliftscoza. the process of manufacturing calcium carbide, and was previously flared at the site (Fig 2) Calcium carbide production Calcium carbide is made by heating calcium carbonate (limestone) to produce lime and subsequently reducing this with …

calcium carbide production emissions - Studio …

Calcium Carbide and Acetylene manufacturing process. Calcium carbide production process. Following figure shows, how CaC 2 and acetylene gas is manufactured by starting from raw materials and what are the physical conditions you should maintain to get higher yield. Carbide compounds can be prepared from strontium and barium metals too.

Emission Factor Documentation for AP-42 Calcium Carbide ...

Emission Factor Documentation for AP-42 Section 11.4 Calcium Carbide Manufacturing Final Report. ... The process for manufacturing calcium carbide is illustrated in Figure 1. Moisture is removed from coke in a coke dryer, while limestone is converted to lime in a lime kiln.

Historie carbid

Willson made the first sale of calcium carbide, 1 ton, to Eimer and Amend, a New York stone and apparatus supply house, on January 29, 1894. Fortune smiled again when, in August 1894, they sold their patents for the use of carbide and acetylene in lighting to a new firm, the Electrogas Company, but retained the rights for stone manufacturing.

Manufacturing Process - MITSUBISHI MATERIALS

The excellent properties of high-temperature hardness and wear resistance of MITSUBISHI CARBIDE is obtained by sintering its main components, Tungsten Carbide, and a binder, Cobalt, having a low melting point using our high level powder metallurgy technology.In the production process, Tungsten Carbide is first produced, then Cobalt is added, and then compound …

Discovery of Calcium Carbide Process | NC DNCR

2-5-2016 · On May 2, 1892, in Spray (now Eden), Canadian chemist Thomas L. Willson accidentally produced calcium carbide and acetylene with an electric-arc furnace. In August, Willson applied for a patent for the new process. By 1897, acetylene was competing with electricity in providing lighting, especially in rural areas and those places where gasoline was …