Iron Ore Crusher Working Process, Iron ore crushing plant ...

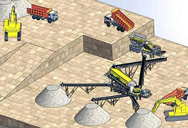

Iron Ore Crusher Working Process. Iron ore dressing, according to the type and nature of ore, can have a variety of different processes. Concentrator generally used coarse crushing, middle crushing and fine crushing three stage.

Iron Ore Crusher Process

Crusher machine for iron ore.In iron ore crushing process include coarse crushing, medium crushing, fine crushing and pulverizing.In iron ore crushing plant, jaw crusher is often to be selected, in medium crushing process, processer usually use impact crusher, and in the fine crushing, short-head type cone crusher is suitable.

The Six Main Steps of Iron Ore Processing | Multotec Canada

When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles. The large particles are diverted back into the crusher and the fine particles will undergo a spiral gravity separation process.

Iron ore crusher, iron ore crusher, i

Iron ore is an important raw material for iron and steel production enterprises. Iron is gradually selected from natural ore (iron ore) by crushing, grinding, magnetic separation, flotation, gravity separation and other procedures. It is a mineral aggregate containing iron or iron compounds that can be economically used.

Iron Ore Beneficiation Plant,Iron Ore Crusher Machine

Iron Ore Beneficiation Process. 1. Iron ore initially through the jaw crusher, a reasonable size of crushed, by lifting machine, feeder evenly into the ball mill, crushing, grinding method. After ball milling iron ore fine material into the next procedure: classification. 2.

crusher iron ore process - hardpressed.co.za

Process Of Mining Iron Ore Jaw Crusher. Process Of Mining Iron Ore Jaw Crusher. Iron Ore Mining Process And Iron Ore Mining . Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screeninghis is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarseommon iron ore crushers are jaw crusher, cone crusher ...

Iron Ore Crusher | Mining, Crushing, Grinding, Beneficiation

Iron Ore Crusher. Iron ore mining methods vary by the kind of ore being mined. You can find four major forms of iron ore deposits worked currently, with respect to the mineralogy and geology of the ore deposits. These are magnetite, titanomagnetite, massive hematite and pisolitic ironstone deposits.

iron ore benification process iron ore crusher equipment

2017-12-12 · iron ore pelletisation process– Rock Crusher Mill iron ore pelletisation process is a leading global manufacturer of crushing and milling equipment (iron ore pelletisation process), also supply individual (iron ore pelletisation process...) crushers and mills as …

Our Mining Process - Iron Ore Company of Canada

IOC’s operations are integrated across our mine and processing plant in Labrador City, Newfoundland and Labrador; our port and stockpile in Sept-Iles, Quebec; and the 418-kilometre railway, run by our subsidiary QNS&L, that joins these two centers of our business.

Iron Ore Crushing Production Line,Iron Ore Crusher, Iron ...

According to the category and characteristic of ore, there are many different processes for iron ore dressing. In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing iron ore. Jaw crusher is usually used for primary crushing; cone crusher is used for secondary and tertiary crushing.

Crusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

Deatil Working Process Of A Iron Ore Crusher

Iron Ore Processing Plants Hongxing Machinery Crusher. The working process of iron ore processing plants 1 the ore is first sent to the jaw crusher for primary crushing then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding 2 the ore powder discharged from the ball mill will be sent to the next procedure classifying

process of quarrying iron ore | Mobile Crushers all over ...

Apr 14, 2015 · Popular Q & A About process of quarrying iron ore. Mining Land (Mining Land) is the largest and leading crusher manufacturer in China, with over 30 year experience ... process of quarrying iron ore - Tech Craft. iron ore in limestone quarries, process crusher iron ore in limestone quarries 354 Views.

Iron ore crushing process,iron ore crushing plant

Iron ore crushing process. Iron ore crushing process is classified into first stage crushing and second stage crushing, also called secondary crushing and fine crushing. Pre-screening is included in secondary crushing, which can significantly increase the production capacity of crusher and improve the working conditions for iron ore crusher.

Machines to Process Iron Ore - goldcrushertrade.com

Iron ore processing machine The ore processing is practically exactly the same as stone crushing method. Firstly, we discover ores from mine and transmit them with the vibrating feeder. Then vibrating feeder pours them into primary ore crusher.

10 Most Popular Iron Ore Beneficiation Machines | HXJQ

PEX jaw crusher, also known as the fine jaw crusher, is an ideal equipment for iron ore crushing. PEX jaw crusher adopts high manganese steel frame, which makes the producing process more reliable and firmer;