A New Process for Cobalt Nickel Separation - Teck

excellent cobalt-nickel separation primary leach liquor by Cyanex 272. However, manganese extraction from the leach liquor along with cobalt could not be avoided, thus increasing the cost of the process. For sulphide ores, there is another alternative; if the ore can be concentrated by flotation, matte smelting is used instead of leaching.

Nickel: smelting, producing-Metalpedia

Nickel is recovered through extractive metallurgy: it is extracted from its ores by conventional roasting and reduction processes that yield a metal of greater than 75% purity. In many stainless steel applications, 75% pure nickel can be used without further purification, depending on the composition of the impurities.

Nickel Mining and Processing: Everything you …

Nickel mining occurs through extractive metallurgy, which is a material science that covers various types of ore, the washing process, concentration and separation, stone processes and the extraction process.

Nickel processing | Britannica

2-5-2020 · Nickel processing, preparation of the metal for use in various products. Demand for nickel-silver was stimulated in England about 1844 by the development of silver electroplating, for which it was found to be the most desirable base. The use of pure nickel as a corrosion-resistant electroplated ...

Nickel Ore | Subnautica Wiki | Fandom

Nickel Ore is a raw material that is found exclusively in the Lost River and some parts of the Inactive Lava Zone. It can be found as a Large Resource Deposit and as loose chunks of ore on the seabed. It is used to create several vehicle upgrades.

Process flowsheet development for beneficiation …

Process flowsheet development for beneficiation of nickel ore Article (PDF Available) in Mineral Processing and Extractive Metallurgy Review 29(1):57-67 · January 2008 with 2,489 Reads

Subnautica Where to find Nickel Ore - YouTube

6-3-2019 · In this Subnautica guide I will show you the best locations in where to find the the Nickel Ore within the Lost River. The lost River is made up of seven sub-biomes and include the stone Fields ...

Mineral processing - Wikipedia

Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching. Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation of gold.

Nickel - Wikipedia

Nickel-plated objects sometimes provoke nickel allergy. Nickel has been widely used in coins, though its rising price has led to some replacement with cheaper metals in recent years. Nickel is one of four elements (the others are iron, cobalt, and gadolinium) that are ferromagnetic at approximately room temperature.

Equipment Used In Separating Nickel From Ore

Equipment used in separating nickel from ore nickel processing britannica nickel processing preparation of the metal for use in various products with iron and sulfur in the ore supplies a portion of the heat required for smelting to produce a lownickel c,Equipment used in separating nickel from ore.

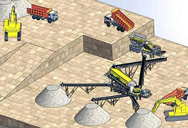

Nickel Ore Processing-Ore ... - Magnetic separation

Nickel Ore Processing. Nickel ore mainly consists of copper-nickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different. Copper-nickel sulfide ore beneficiation methods, the most important is the flotation, magnetic and re-election is usually secondary dressing method.

Nickel Metal: Its Properties, History, Production & …

The separation process for nickel is highly dependent upon the type of ore. Nickel sulfides, such as those found in the Canadian Shield and Siberia, are generally found deep underground, making them labor-intensive and expensive to extract.

separation of nickel from nickel ore - evajorritsma.nl

Nickel Ore Processing - Magnetic Separation Process. Nickel ore mainly consists of copper-nickel sulfide ore and nickel oxide ore, beneficiation and proc. Chat Now. Nickel - Minerals Council of Australia.

Froth Flotation of Ultramafic Nickel Ore

25-4-2010 · Froth Flotation of Ultramafic Nickel Ore - No Pre-treatment ... the three major sources of Nickel. ... sulphide particles in case of Ultramafic ore reveals no separation …

industrial separation of nickel from nickel ore

Nickel ore beneficiation technology – Stone Crusher Machine … Copper is harmful impurities in the nickel ore smelting, industrial recovery value in the copper-nickel ore, copper grade, copper-nickel separation is an important topic … Cobalt extraction techniques – Wikipedia, the free encyclopedia. Several methods exist for the ...

Nickel Ore - an overview | ScienceDirect Topics

This and the high cost of working underground explain why underground orebodies must contain higher grades of nickel ore than open-pit orebodies. Ore grade has a direct effect on mine investment costs expressed in US$ per annual tonne of nickel. Consider two identical ore bodies, one containing 1.25% Ni ore and the other containing 2.5% Ni ore.

How nickel ore is separated - beckers-muehle.de

Nickel Ore Separation. Xinhai has manufactured nickel ore mining equipment for many years nickel ore copper sulfide nickel ore magnetic separating and gravity separating are the Contact US Nickel Wikipedia Nickel is a stone element with symbol Ni and atomic number 28 It is a silvery white lustrous . NickelCobalt Separation Innovation Metals Corp

Enhanced methods for nickel recovery from low …

Enhanced methods for nickel recovery from low-grade ores and bleed streams. ... high-grade nickel ore has Ni content greater than 1.8%, middle-grade nickel ore has Ni content between 1.3-1.7%, ... SX processes often report the separation of nickel …

Pre-concentration of nickel in laterite ores using ...

Of course, upgrading nickel using magnetic separation highly depends on the ore mineralogy and mineral liberation, and if nickel is associated with magnetic minerals. Table 3 also shows that the percentage of iron increases (by ~70%) in the magnetic product for ores S and I, but not for ore L.

Separation of Cobalt and Nickel from Aqueous …

Separation of cobalt and nickel from sulfate media was investigated, using a extraction system of 30% 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester …