Primary Crushing Require - societasole.it

Primary crushing reduces the large pieces to a size which can be handled by the downstream machinery. Some crushers are mobile and can crush rocks as large as 1.5 meter (60 inches). Primarily used in-pit at the mine face these units are able to move with the large infeed machines (mainly shovels) to increase the tonnage produced.

Primary Crushing And Grinding - photodesign …

Primary Crushing And Grinding. 2019-9-27the crushing process often requires different stages of grinding, since there is no crusher or mill capable of converting large mineral formats into micronized fineshus, our range of crushers and mills covers the whole size reduction process, from the primary crushing stage to the refining grinding.

Primary Crusher Selection & Design

No crusher, when set at any given discharge opening, will make a product all of which will pass a screen opening of the same dimensions as the given discharge opening. In in-pit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system.

Primary Crushing Process | Pdf Size Reduction By …

Also primary gyratories require quite a massive foundation primary crushing with impact crushers the primary impact crusher offers high capacity and is designed to accept large feed sizes the primary impact crushers are used to process from 200 th up to 1900 th and feed sizes of up to 1830 mm 71 in the largest model. More Details

Primary Crusher - an overview | ScienceDirect …

Primary gyratory crushers are used in the primary crushing stage. Compared to the cone type crusher, a gyratory crusher has a crushing chamber designed to accept feed material of a relatively large size in relation to the mantle diameter. The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge ...

Primary Crushing - Mineral Processing & …

The primary crushing setup is closely linked to the quarrying or mining operation, and it is only by careful adjustment of all equipment selections to the general plan of operation that optimum operating results may be realized.

limit of particle size required for primary crushing

Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry. With the development of our liming, we would like to help more and more customers start their business in mining and construction industries, offer them the best solution, much more advanced machinery and better service.

Crushing Systems - FLSmidth

require maintenance of pre-load. • Top serviceable eccentric and hydraulic piston are faster, more efficient, and safer than a traditional bottom service gyratory crusher. • Threadless mainshaft design improves strength by minimizing peak stresses during demanding crushing operations. • FLSmidth designs custom chamber profiles for each

Crushers - All crusher types for your reduction …

Primary crushing with impact crushers. The primary impact crusher offers high capacity and is designed to accept large feed sizes. The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model. Primary impact crushers are generally used in nonabrasive applications and where the production of fines is …

Crusher - Wikipedia

Primary crushing reduces the large pieces to a size which can be handled by the downstream machinery. Some crushers are mobile and can crush rocks as large as 1.5 meter (60 inches). Primarily used in-pit at the mine face these units are able to move with the large infeed machines (mainly shovels) to increase the tonnage produced.

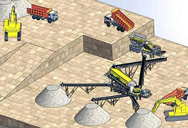

Primary Crushing Plants | TAKRAF

Primary crushing plants are the first step in material processing and/or link between mining truck and belt conveyor, train or road. Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twin-shaft sizers, double-roll crushers, impact crushers or hammer crushers, depending on material properties and required throughputs.

Capacity And Energy Required Of A Primary …

Primary crusher capacity and energy required of a primary crusher. Jul 20, 2012 ·  Primary crusher capacity and energy required of a primary crusher liming Heavy Industry (shanghai) to provide you with more options: more than 400 kinds of …

primary crushing - Deutsch-Übersetzung – Linguee Wörterbuch

Designed for primary crushing, its rugged design, but compact size, makes it easier to transport from one location to another (Fig. 1). at-online.info Die für die Vorzerklei-nerung ausgelegte Anlage mit einer robusten Konstruktion kann aufgrund ihrer kompakten Größe leichter von einem Standort zum anderen transportiert werden (Bild 1).

primary crushing and secondary crushing

boulders from finer rocks that do not require primary crushing, thus reducing the load to the primary ... the scalping screen is processed in the secondary crusher. Get Quote; Impact Crushers & Cement Crushers - Rotor Impact Crusher ...

Pai Primary Crushing Training Youtube - …

Therefore, primary gyratories require quite a massive foundation. The cone crusher is a modified gyratory crusher. PAI Primary Crushing Training YouTube. Jan 08, 2016 In this training module, well cover the characteristics of a gyratory crusher thats designed to be the. Get Price

primary crushing plant - Deutsch-Übersetzung – Linguee ...

A typical rock crushing plant will usually involve several successive stages, each of which achieves an increasing level of rock fineness and involves a number of possible technologies: the first stage of crushing, where large rocks obtained from blasting or otherwise are crushed, is referred to as primary crushing.

Primary Crushing Plant Mining | Primary …

Primary Crushing Takraf, Primary crushing plants primary crushing primary crushing plants are the first step in material processing andor link between mining truck and belt conveyor train or road Primary Crushing Plant Mining

Difference Between Primary Secondary And …

Difference Between Primary Secondary And Tertiary Crushing This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing be done in stages.